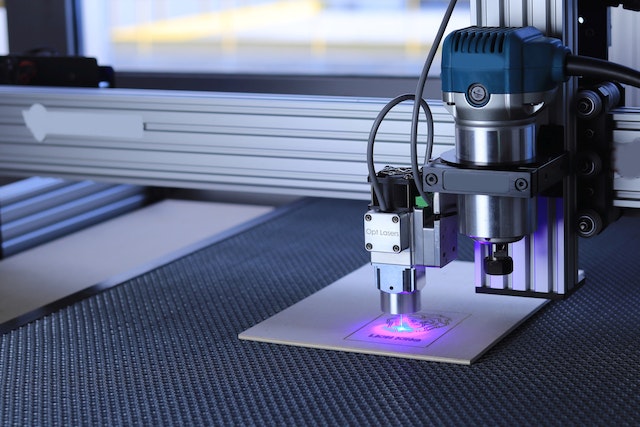

Laser-cutting systems have changed the manufacturing sector. They perfectly re-create designs made on computers in just a matter of seconds or minutes.

You will be surprised by the number of applications laser cutting services cover, and the best way to find out is to know how it works.

What Laser Cutting Is

It refers to the process of cutting materials through a laser beam. Depending on the requirements, a laser beam may help to trim down materials or cut them into more complex shapes, which conventional drills struggle with.

Laser-cutting machines may be used to engrave and drill materials. A laser cutting method is considered versatile as it may cut a wide range of materials with different thicknesses.

The Working Principle of Laser Cutting

The process of laser cutting begins with your idea. Once you develop it, you may use CorelDRAW to prepare graphics or other 2D software and then send data to the laser.

Using a laser head, laser cutters generate high-powered laser beams directed at the materials. Then the beam burns, vaporizes, or melts through materials based on the material’s properties and the laser’s power.

The laser normally uses motion control systems or unique programming systems referred to as G-code to control the laser’s movements.

Applications

Laser-cutting systems can be used in different applications. They are commonly used for production tasks, but small businesses, hospitals, schools, and hobbyists also use laser cutting systems for various purposes.

Among the major applications of laser cutting systems is cutting metals. Metals are a necessity in most industries – so laser cutter is quite common. A good example of this is when companies shape car bodies or cellphone cases.

Types of Laser Cutting Systems

The laser cutting process is broken down into three major techniques. These include Nd:YAG (neodymium yttrium-aluminum), Nd (neodymium), and CO2 laser. All these three types may be used for welding.

The CO2 laser involves passing current through a gas mix or using a new RF (radio frequency) energy technique. The radio frequency method has external electrodes, thus, avoiding problems associated with electrode erosion. Apart from these three laser cutting types, you will also find other types:

- Fiber laser cutter

- Crystal laser cutter

- Gas laser cutters

Why Laser Cutting Process

Firstly, a laser cutting system can produce different parts with high precision. A laser cutter is very accurate and can create complex cuts and great details, allowing you to design almost everything.

Laser cutting machines are also automated, saving you time during production. All that will be left for you and your workers to do is to move materials. This lowers production costs and results in low material wastage.

The Bottom Line!

There is a lot involved during the laser cutting process, and understanding how it works can be difficult. However, in a nutshell, air/gas produces electricity, then electricity gets converted into power, which is focused to a point, and lastly, the laser comes out. If you are out in the market for a good laser-cutting machine, take your time to research and ask for recommendations from people you can trust.